Factory Free sample Biomass Generator - Chelated Iron-Based Nutrient Catalyst Solution – Mingshuo

Factory Free sample Biomass Generator - Chelated Iron-Based Nutrient Catalyst Solution – Mingshuo Detail:

Chelated Iron-Based Nutrient Catalyst Solution

The iron-based nutrient solution functions as a catalyst for wet oxidation of hydrogen sulfide removal, characterized of directly converting H2S into elemental sulfur.

Advantages:

Simple process, adjustable sulfur capacity, large flexibility

Environmental friendly, non-toxicity

Regenerable, no waste disposal problem

H2S, COS removal, by-product elemental sulfur

Adsorption: H2S + 2Fe3+ = 2H+ + S + 2Fe2+

Regeneration: 1/2 O2 + H2O + 2Fe2+ = 2OH- + 2Fe3+

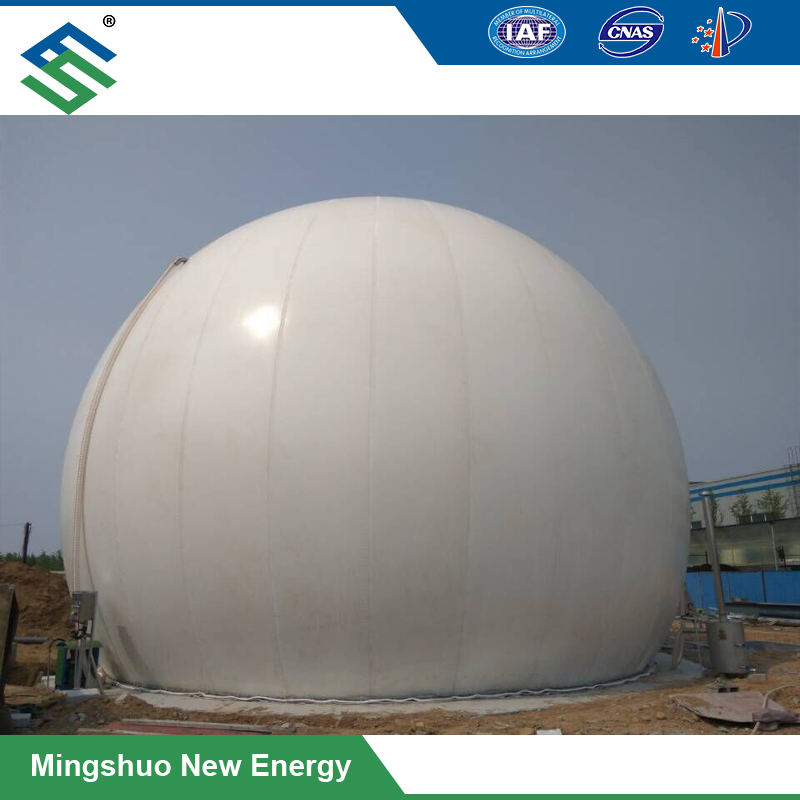

Product detail pictures:

Related Product Guide:

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Factory Free sample Biomass Generator - Chelated Iron-Based Nutrient Catalyst Solution – Mingshuo, The product will supply to all over the world, such as: Maldives , Saudi Arabia , Guatemala , We are looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states.

With a registered capital of CNY 88 million, Mingshuo Environment Technology Group Co., Ltd. is founded in 2004. It is a high-tech enterprise dedicated to purifying sulfur-containing gases and realizing high-value utilization of organic wastes.

Adhering to the corporate spirit of integrity, innovation and mutual benefit, Mingshuo has gradually developed into a high-tech enterprise integrating R&D, consulting, design, manufacturing, construction and operation. It can provide comprehensive and sustainable ”one-stop” environmental services and overall solutions. The Group has passed ISO quality control, environmental management, occupational health and safety management system certifications, has professional construction qualifications for environmental engineering, D type pressure vessel manufacturing qualifications. It is also “Weifang Enterprise Technology Center”, “Weifang City Desulfurization and Denitrification Engineering Laboratory”, “Weifang City Biogas Equipment Engineering Technology Research Center”. The products have won the honorary titles of “China Green Products” and “China Famous Brand”. The chairman of the Group won the honorary title of “Shandong Province Circular Economy Person of the Year”.

Mingshuo’s products are divided into three series: desulfurizer and desulfurization equipment, biogas equipment, titanium, nickel and the like pressure vessel equipment. The desulfurizer and desulfurization equipment are mainly used for the treatment of biogas, natural gas, oilfield associated gas, shale gas, and other sulfur-containing gases for users in the fertilizer, coking, steel plant, and petroleum refining industries. The biogas equipment is mainly used for the treatment of organic waste such as livestock and poultry manure, kitchen waste, organic waste, straw and sewage. It realizes high-value utilization and turns waste into treasure. Titanium, nickel and the like pressure vessel is mainly used in oil refining, pharmaceutical, fertilizer, desalination, chemical and other industries. The Group has long-term cooperation with large domestic enterprises such as CNPC, Sinopec, COFCO, CSSC, Energy China, Beijing Drainage Group, INFORE ENVIRO, China Huadian Corporation Ltd., and Weichai Group. The Group has independent import and export rights, and has provided complete system services for lots of customers in the United States, Japan, Malaysia, the Philippines and other countries along the Belt and Road.

Mingshuo Environmental Group is committed to the development of environmental undertakings, always adhering to the development concept of “Cherish the Limited, and Create the Infinite”, and wish to go hand in hand with you to create a better future!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!