Storskala biogassanlegg for behandling av organisk avfall

Anaerob fordøyelse(AD) er en veletablert prosess for produksjon av fornybar energi der biomasse brytes ned og konverteres til biogass (en blanding av metan, karbondioksid og spor av andre gasser) av mikroorganismer. Miljøet inne i en biodigester er sammensatt, avhengig av sammensetningen av råstoffet og driftsforholdene, og noen av biproduktene er etsende for visse strukturelle materialer. Det er viktig å minimere vedlikehold fordi hver gang annonseprosessen blir avbrutt, tar det 3-4 uker før produksjonen starter opp igjen.

AD blir til et stadig populært gjenvinningsvalg som en tilnærming for å få energi, kompost og næringsverdi ut av kasserte organiske stoffer og hjelper til med å kontrollere metanutslipp som er en meget potent klimagass. Biogass kan brukes som drivstoff i gassrørledninger, forbrent for å produsere strøm eller komprimert til et kjøretøyets drivstoff. De resterende faste stoffer og væske er gode næringsrike avlingsgjødsel.

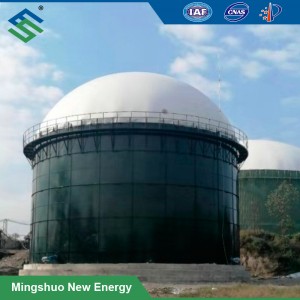

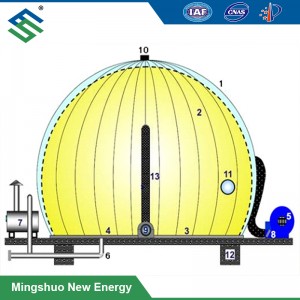

ECPC samlet tankbestår av elektroforese stålplate, spesielt tetningsmateriale, selvlåsende bolt og andre materialer. Det kan brukes til å forsegle lagring av gass, væske og fast stoff i biogassingeniør, avløpsbehandling, kornlagring og petrokjemisk industri. I biogassprosjekt er samlet tank en beholder for lagring og gjæring av forskjellige organiske forbindelser.

Det dannes en sterk bindkraft mellom det elektroforetiske laget og stålplaten. Det elektroforetiske laget kan ikke bare forhindre at tanken korrosjon, men tilbyr også utmerket kjemisk motstand mot en rekke syrer og alkaliner. I mellomtiden har det en utmerket slitestyrke.

Størrelsen på hver samlet tank er fleksibel(50m3til 3300m3anbefales). Vi kan tilby skreddersydde tjenester i henhold til dine krav. Dimensjonen til en standard 1000m3samlet tank: φ 11,46m * h 9,6m.

| Punkt | Cubage (m³) | Diameter (mm) | Høyde (mm) | Matchende biogass lagringstank cubage (m³) | Bemerket |

| 1 | 200 | 6875 | 5400 | 65 | Standard |

| 2 | 300 | 7640 | 7200 | 100 | Standard |

| 3 | 400 | 8400 | 7200 | 135 | Standard |

| 4 | 500 | 9930 | 7200 | 150 | Standard |

| 5 | 600 | 9930 | 7800 | 200 | Standard |

| 6 | 700 | 10700 | 7800 | 235 | Standard |

| 7 | 800 | 11460 | 7800 | 250 | Standard |

| 8 | 1000 | 11460 | 9600 | 350 | Standard |

| 9 | 1500 | 13750 | 10200 | 500 | Standard |

| 10 | 2000 | 15280 | 11400 | 600 | Spesiell |

| 11 | 3000 | 16040 | 15000 | 1000 | Spesiell |

Ytelse og egenskaper

•Stabil kvalitet, god korrosjonsmotstand, lang levetid, høy temperaturmotstand

•Høy strengende gummihette med selvlåsende bolt, forsegling tett, god antiseptisk effekt

•tetningsmasse med høye temperaturresistens, anti-mikrobiell korrosjon

•rask installasjon, utvidelse og migrasjon

Applicaple arbeidsprosess

CSTR: Kontinuerlig omrørt tankreaktor

Usr: up-flow slamreaktor

UASB: Up-Flow Anaerobic Sludge Teppe

Fysiske egenskaper

Beleggfarge: Standardfargen er mørkegrønn eller skreddersydd etter kundenes krav.

Beleggstykkelse: 0,25-0,45 mm, både inne og ute er belagt.

Syre-alkalisk motstand: Arbeid riktig under pH-verdi på 3-11.

Adhesjon: 3.450 N/cm.

Elastisitet: 500 kN/mm.

Hardhet: 6.0 (av MOHS -skala)

Prosjektdisplay: Jiangsu Taizhou meieriindustri

Video

Med en registrert kapital på 88 millioner CNY, er Mingshuo Environment Technology Group Co., Ltd. grunnlagt i 2004. Det er et høyteknologisk foretak dedikert til å rense svovelholdige gasser og realisere høy verdi utnyttelse av organisk avfall.

Ved å følge bedriftens ånd av integritet, innovasjon og gjensidig fordel, har Mingshuo gradvis utviklet seg til et høyteknologisk foretak som integrerer FoU, rådgivning, design, produksjon, konstruksjon og drift. Det kan gi omfattende og bærekraftige ”one-stop” miljøtjenester og overordnede løsninger. Gruppen har bestått ISO -kvalitetskontroll, miljøledelse, sertifisering av arbeidshelse og sikkerhetsstyringssystem, har profesjonelle konstruksjonskvalifikasjoner for miljøteknikk, Dype trykkfartøyproduksjonskvalifikasjoner. Det er også "Weifang Enterprise Technology Center", "Weifang City Desulfurization and Denitrification Engineering Laboratory", "Weifang City Biogas Equipment Engineering Technology Research Center". Produktene har vunnet æretitlene til "China Green Products" og "Kina berømte merke". Formannen for gruppen vant æretittelen "Shandong Province Circular Economy Person of the Year".

Mingshuos produkter er delt inn i tre serier: Desulfurizer og Desulfuriseringsutstyr, biogassutstyr, titan, nikkel og lignende trykkfartøyutstyr. Desulfurizer og avsvovlingsutstyr brukes hovedsakelig til behandling av biogass, naturgass, oljefelt assosiert gass, skifergass og andre svovelholdige gasser for brukere i gjødsel, kokende, stålanlegg og petroleums raffineringsindustri. Biogassutstyret brukes hovedsakelig til behandling av organisk avfall som husdyr og gjødsel, kjøkkenavfall, organisk avfall, halm og kloakk. Det innser bruk av høy verdi og gjør avfall til skatt. Titan, nikkel og lignende trykkbeholder brukes hovedsakelig i oljeraffinering, farmasøytisk, gjødsel, avsalting, kjemisk og andre næringer. Gruppen har langsiktig samarbeid med store innenlandske virksomheter som CNPC, SINOPEC, COFCO, CSSC, Energy China, Beijing Drainage Group, Infors Enviro, China Huadian Corporation Ltd., og Weichai Group. Gruppen har uavhengige import- og eksportrettigheter, og har levert komplette systemtjenester for mange kunder i USA, Japan, Malaysia, Filippinene og andre land langs beltet og veien.

Mingshuo Environmental Group er forpliktet til utvikling av miljøforetak, og holder seg alltid til utviklingsbegrepet å "verne det begrensede, og skape det uendelige", og ønsker å gå hånd i hånd med deg for å skape en bedre fremtid!