Tele-fua biogas toto mo otaota otaota togafitiga

Anaerobic devogestion(ADD) o se mea fou faʻavaeina mo le faʻaleleia o le malosi o le malosi o le Biomas ua motusia i lalo ma liua i le biogas (o se paie o isi moa) e mimiti. O le siʻosiʻomaga i totonu ole IOS ifo o loʻo faigata, faʻalagolago i luga o le faʻavaeina o faiga 'ava ma gaioiga faʻagaioiga, ma nisi o oloa e faʻaleagaina i nisi o mea faʻatulagaina. E taua le faʻaitiitia o le tausiga aua o taimi uma o le faʻagaioiga faʻaumatia, e faʻapena le 3-4 vaiaso mo le toe amataina.

STA o loʻo liliu i totonu o se masani-lauiloa filifiliga filifiliga o se auala e maua ai le malosi, confust ma meaʻai faʻatatauina o le detectid conthane o le tino o le eleele. E mafai ona faʻaaoga le biogas o se suauu i totonu o le kesi kesi, tuʻufaʻatasia e maua ai le eletise pe faʻamalosi i totonu o se taʻavale afi. O le maumautui sosolo ma suavai o lelei-mauoa-mauoa rop stop fetilaisa.

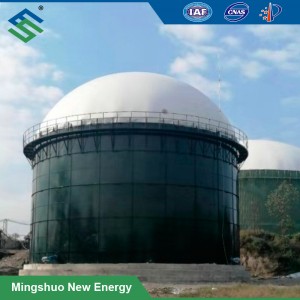

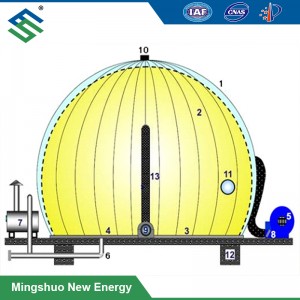

ECPC faapotopotoina taneo loʻo faia i luga o le eletise eletise steate, o mea faʻapitoa (faʻapitoa o le faʻamaufaʻailoga E mafai ona faʻaaogaina mo le teuina o le teuina o kesi, suavai ma le mautu i le biogas inisinia, suʻi o le suavai, saito o saito ma peritrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrokmacal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal teuina ma pefurrochocal I totonu o le Biogus Project, e faʻaputuputu Tak o se atigipusa mo le teuina ma le faʻamalosi o le tele o meaola o meaola.

O se malosi puipuia malosi e fausia i le va o le eletise eletise ma uamea ipu. O le eletise eletise e le gata ona taofia ai le tane mai le porosion ae e ofoina atu foi le lelei vailaau tetee i le tele o gaioiga ma alkolines. Ile taimi nei, e iai lona taumamafa tutusa le tetee.

O le tele o le mageso uma tane tane e fetuutuunai(50m3i le 3300m3ua fautuaina). E mafai ona matou tuʻuina atu ni tautua faʻapitoa e tusa ma au manaʻoga. O le tulaga o se masani 1000m3Faaputuputu Tank: φ 11.46m * H 9.6m.

| Aitema | Cubge (m³) | Lapoa (mm) | Maualuga (mm) | Faafetaui Biogas Teuina Tank Cubge (M³) | Taʻutaʻua |

| 1 | 200 | 6875 | 5400 | 65 | Tulaga |

| 2 | 300 | 76400 | 7200 | 100 | Tulaga |

| 3 | 400 | 8400 | 7200 | 135 | Tulaga |

| 4 | 500 | 9930 | 7200 | 150 | Tulaga |

| 5 | 600 | 9930 | 7800 | 200 | Tulaga |

| 6 | 700 | 10700 | 7800 | 235 | Tulaga |

| 7 | 800 | 11460 | 7800 | 250 | Tulaga |

| 8 | 1000 | 11460 | 9600 | 350 | Tulaga |

| 9 | 1500 | 13750 | 10200 | 500 | Tulaga |

| 10 | 2000 | 15280 | 11400 | 600 | Faapitoa |

| 11 | 3000 | 16040 | 15000 | 1000 | Faapitoa |

Faatinoga ma uiga

•Nofoaga e mafai ai, o le uiga o le mama o le tino

•maualuga strenth paʻu pulou ma le tagata lava ia-lokaina le paʻu, faʻamaufaʻailoga, lelei le lelei

•Sealant ma le vevela-vevela tetee, anti microbicial lamatia

•vave faapipiiina, faalauteleina ma malaga

Talosaga Galuega galue

CSTR: O le faʻaauau pea o le taʻe

USR: Up-Flow-Flow SpringGen

OASB: Up-Flow Aaerrobic Shanden Blonket

Tulaga o le Malo

O le lanu o le lanu: O le lanu masani o le lanu uliuli lanumeamata pe fetuunai e tusa ai ma tagata faatau manaoga.

O le mafiafia mafiafia: 0.25-0.45mm, i totonu ma fafo o le kamuta.

ACID-Alkali tetee: Galue lelei i lalo o le ph aoga o le 3-11.

Aiaiga: 3,450 n / cm.

ElesticIty: 500 la / mm.

Faigofie: 6.0 (e le Mohs fua)

Project Replation: Jiangu Taizhou Dairy Yourry

Ata

Faatasi ai ma se tupe lesitala o le CONY 88 miliona, MINGHOOO GALUEGA FAAPITOA GOLOKALAMSAGA COR., LTD. O LE O LE CEN-TEMPER MA LE NOFOAGA MANUCK.

Faʻafeiloaʻi i le Vaega Autu o Amio Amio Amio Amio Amio Amio Amio Amio Amio Amio Amio Amiotonu, o Masaniga Faamanuiaga, na faʻasolosolo malie lava Mafano i totonu o se kamupani maualuga-tekonolosi R & D, fale gaosi, fausiaina, fausiaina, fausiaina, fausiaina, fausiaina, fausiaina, fausiaina ma gaioiga. E mafai ona fua maia i le a iai se mea lautele ma gafataulimaina "tasi-taofi" galuegateofia ma fofo lautele. Ua pasia e le kulupu le uiga lelei o le amio pulea, siosiomaga o le siosiomaga, o gaioiga o le soifua maloloina o polokalame, e iai tomai faʻapolofesa e fausia ai faʻailoga o le Siosiomaga. O le "Weifgang Antitai Auai Aurote Center", "o le Orfieng City Countrour ma Detonication Enboractory", "O le Aroning Discorgitory Intericas Intericas Intericas Mechorid Megy O oloa na manumalo i suafa mamalu o le "Saina Greft Oloa" ma "Saina lauiloa ituaiga". O LE TAʻITAʻITA a LE VAEGA Na manumalo le Vaega Faʻamaoni o le "Shandndong Itumalo Porntiure Tamaʻitaʻi Tagata faigaluega o le tausaga".

O oloa a Mingshuo e vaevaeina i le tolu faasologa: O mea e maua mai ai, o mea leaga o meatotino, Titani, Nicipall ma le fiafia i masini. O le Despulfirizer ma Doullulations masini ua faʻaaogaina tele mo le togafitia o le biogas, kesi masani, o suauʻu, kuka, ma le suauʻu ua faamama ai. O le biogas meafaigaluega o loʻo faʻaaogaina tele mo le togafitia o otaota o maʻi o loʻo avea ma lafumanu ma ulavale, umukuka otaota, otaota o otaota, vao ma otaota. E faʻatino le maualuga maualuga o alavai ma liliu ai le otaota i le gafa. Titanilele, Nickel ma e pei o le vaʻavaʻaia o le vaʻa vaʻa, e faʻaaogaina tele i le supa lele, vailaʻau palama, fetilaisa, kesi ma isi falefaigaluega. O le kulupu ua leva ona galulue faʻatasi ma le tele o pisinisi tetele pei o Cnpc, Silpepec, CSC, Bainc, Bain Scadiard LtD., ma le kulupu o Arero. E iai pea le tutoʻatasi o le vaega i le faʻaulufaleina mai ma Exvupepopopoponanau i fafo, ma ia tuʻuina atu le faʻamaeʻaina faiga atoa o tagata faʻatau ile tele o tagata faʻatau i Amerika, Iapani, Melatia ma isi nuʻu.

O le kulupu o le Siosiomaga o loʻo faia le atinaʻeina o le siosiomaga, e faʻamalosia pea le tulaga faʻavae o le atinaʻeina o se "mea e le gata