Závod bioplynu vo veľkom meradle na ošetrenie organickým odpadom

Anaeróbne trávenie(AD) je dobre zavedený proces výroby obnoviteľnej energie, pri ktorom sa biomasa rozkladá a premieňa na bioplyn (zmes metánu, oxidu uhličitého a stopy iných plynov) mikroorganizmami. Prostredie vo vnútri biodigesteru je zložité v závislosti od zloženia suroviny a prevádzkových podmienok a niektoré vedľajšie produkty sú korozívne k určitým štrukturálnym materiálom. Je nevyhnutné minimalizovať údržbu, pretože zakaždým, keď je proces reklamy prerušený, trvá 3-4 týždne, kým sa výroba opäť začína.

AD sa mení na stále populárnu voľbu recyklácie ako prístup k získaniu hodnoty energie, kompostu a živín z vyradených organických látok a pomáha regulovať emisie metánu, ktoré sú vysoko účinným skleníkovým plynom. Bioplyn sa môže používať ako palivo v plynovodoch plynu, ktoré sú zhoršené na výrobu elektriny alebo stlačené do paliva vozidla. Zvyškové tuhé látky a tekutina sú dobré hnojivá plodiny bohaté na živiny.

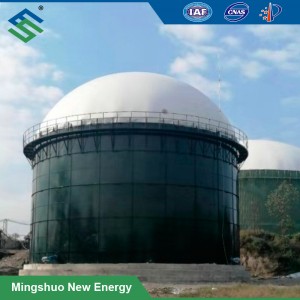

Zostavený nádrž ECPCsa skladá z elektroforéznej oceľovej dosky, špeciálneho tesniaceho materiálu, samoliečkovej skrutky a iných materiálov. Môže sa použiť na utesnenie skladovania plynu, tekutiny a tuhého inžinierstva, úpravy odpadových vôd, skladovania obilia a petrochemického priemyslu. V projekte Biopys je zostavený nádrž na ukladanie a fermentáciu rôznych organických zlúčenín.

Medzi elektroforetickou vrstvou a oceľovou doskou sa tvorí silná viazaná sila. Elektroforetická vrstva môže nielen zabrániť korózii nádrže, ale tiež ponúka vynikajúcu chemickú odolnosť voči rôznym kyselinám a alkalicim. Medzitým má vynikajúci odpor oderu.

Veľkosť každej zostavenej nádrže je flexibilná(50 m3do 3300 m3sa odporúča). Môžeme poskytovať služby prispôsobené podľa vašich požiadaviek. Rozmer štandardného 1 000 m3Zostavená nádrž: φ 11,46 m * H 9,6 m.

| Položka | Cubage (m³) | Priemer (mm) | Výška (mm) | Zodpovedajúce bioplynu skladovacia nádrž Cubage (m³) | Známy |

| 1 | 200 | 6875 | 5400 | 65 | Norma |

| 2 | 300 | 7640 | 7200 | 100 | Norma |

| 3 | 400 | 8400 | 7200 | 135 | Norma |

| 4 | 500 | 9930 | 7200 | 150 | Norma |

| 5 | 600 | 9930 | 7800 | 200 | Norma |

| 6 | 700 | 10700 | 7800 | 235 | Norma |

| 7 | 800 | 11460 | 7800 | 250 | Norma |

| 8 | 1 000 | 11460 | 9600 | 350 | Norma |

| 9 | 1500 | 13750 | 10200 | 500 | Norma |

| 10 | 2000 | 15280 | 11400 | 600 | Výnimočný |

| 11 | 3000 | 16040 | 15000 | 1 000 | Výnimočný |

Výkon a vlastnosti

•Stabilná kvalita, dobrý odpor korózie, dlhá životnosť, vysoký teplotný odpor

•Vysoký strih gumový uzáver s samočistiackou skrutkou, tesný tesný, dobrý antiseptický účinok

•tmel s vysokou teplotou rezistencie, proti mikrobiálnej korózii

•Rýchla inštalácia, rozširovanie a migrácia

Pracovný proces aplikácie

CSTR: Kontinuálny miešaný tankový reaktor

USR: Reaktor na kalový kalový tok

UASB: Up-flow anaeróbna kalová prikrývka

Fyzikálne vlastnosti

Farba povlaku: Štandardná farba je tmavo zelená alebo prispôsobená podľa požiadaviek zákazníkov.

Hrúbka povlaku: 0,25-0,45 mm, vo vnútri aj zvonku je potiahnutá.

Odolnosť kyseliny-alalita: Správne pracujte pri hodnote pH 3-11.

Adhézia: 3 450 N/cm.

Elasticita: 500 kN/mm.

Tvrdosť: 6.0 (podľa Mohs Scale)

Zobrazenie projektu: mliekarenský priemysel Jiangsu Taizhou

Video

S registrovaným hlavným mestom 88 miliónov CNY spoločnosť Mingshuo Environment Technology Group Co., Ltd. je založená v roku 2004. Je to high-tech podnik venovaný čisteniu plynov obsahujúcich síru a realizácii využitia organických odpadov s vysokou hodnotou.

Mingshuo, ktorý sa dodržiava podnikového ducha integrity, inovácií a vzájomného prínosu, sa postupne vyvinul do high-technikového podniku integrujúceho výskumu a vývoja, konzultácie, dizajnu, výroby, výstavby a prevádzky. Môže poskytovať komplexné a udržateľné „jednorazové“ environmentálne služby a celkové riešenia. Skupina schválila kontrolu kvality ISO, riadenie životného prostredia, osvedčenia systému riadenia zdravia a ochrany zdravia, má profesionálnu výstavbu kvalifikácie pre environmentálne inžinierstvo, kvalifikáciu výroby tlakových plavidiel typu D. Je to tiež „Weifang Enterprise Technology Center“, „Laboratórium desulfurizácie a denitrifikácie Weifang City“, „Výskumné technologické technologické centrum technológie Weifang City Biopy Engineering Engineering Engineering“. Výrobky získali čestné tituly „China Green Products“ a „China slávna značka“. Predseda skupiny získal čestný titul „Osoba obehovej ekonomiky v provincii Shandong“.

Výrobky spoločnosti Mingshuo sú rozdelené do troch sérií: desulfurizátor a desulfurizačné zariadenie, bioplynu, titán, nikel a podobné tlakové nádoby. Zariadenie na usilfurizátor a desulfurizačné zariadenie sa používajú hlavne na spracovanie bioplynu, zemného plynu, plynu spojeného s ropou, bridlicový plyn a ďalšie plyny obsahujúce síru pre používateľov v odvetví hnojív, koksentov, oceľových rastlín a ropných odvetví. Zariadenie na bioplyn sa používa hlavne na spracovanie organického odpadu, ako sú hnoj hospodárskych zvierat a hydiny, kuchynský odpad, organický odpad, slama a odpadové vody. Realizuje využitie vysokej hodnoty a premieňa odpad na poklad. Titán, nikel a podobné tlakové nádoby sa používajú hlavne pri rafinácii ropy, farmaceutickej, hnojivách, odsoľovaní, chemických a iných odvetviach. Skupina má dlhodobú spoluprácu s veľkými domácimi podnikmi, ako sú CNPC, SinoPEC, COFCO, CSSC, Energy China, Peking Draximage Group, Spoločnosť Enviro, China Huadian Corporation Ltd. a Weichai Group. Skupina má nezávislé práva na dovoz a vývoz a poskytla kompletné systémové služby pre veľa zákazníkov v Spojených štátoch, Japonsku, Malajzii, Filipínach a ďalších krajinách pozdĺž pásu a cesty.

Spoločnosť Mingshuo Environmental Group sa zaviazala rozvíjať environmentálne podniky, vždy dodržiava koncept rozvoja „Cherish the Limited and Freation The Infinite“ a chcú s vami ísť ruka v ruke, aby ste vytvorili lepšiu budúcnosť!